|

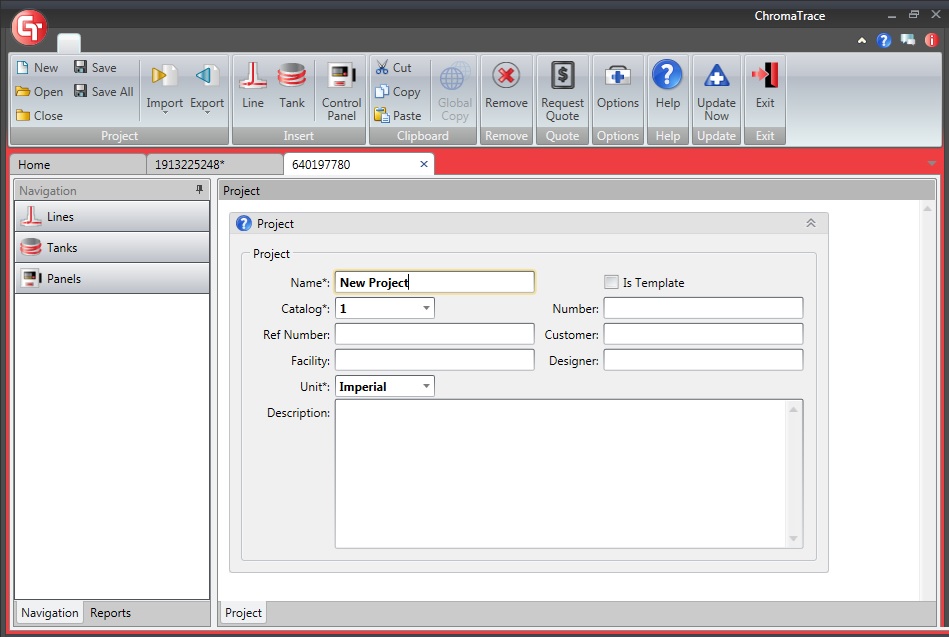

Chromalox Releases ChromaTrace® 3.0 Software

for Heat Trace Project Design

PITTSBURGH — March 6, 2013 — Chromalox®, a leading manufacturer of electric heat and control products has released ChromaTrace 3.0, an enhanced version of its custom heat trace project design software. This software is suitable for use by design engineers and maintenance personnel in virtually any industrial setting that includes piping systems, such as petrochemical processing, waste water treatment and chemical processing where temperature maintenance is required for uninterrupted operation.

The ChromaTrace 3.0 user will be able to get IEEE-compliant heat trace calculations quickly and create a complete bill of materials to aide in the purchasing process. They’ll be able to manage their heat trace projects and drawings, and tie pipe and tank data to specific drawings. The design engineer may set up various scenarios to find the most cost-effective solution for their process.

ChromaTrace 3.0 is free, and may be downloaded here.

It’s complete with new, easy-to-use features including:

• Visual tree structure for pipes, tanks and control panels

• Enhanced data handling via Excel import and export functions

• Calculations compliant with the latest version of IEEE515

• Links to Chromalox website for quick download of submittal data

• Enhanced reporting package with instant export to Microsoft® Excel, Word or Adobe® PDF format

• Enhanced Panel Circuit Assignment features including

o Panel Model Number Configuration

o Main Disconnect / Main Breaker Sizing function

o Circuit / Line current tracking per panel circuit

o Panel Installer report showing line / tank assignments and total circuit currents

• Request for Quote feature – one click eQuote request for your project

• Back-end data link to AutoCAD for automated isometric drawings

• Enhanced revision and change control

”ChromaTrace 3.0 is a highly advanced heat trace system design tool,” said Mark Crombie, Director of Heat Trace for Chromalox.

“We anticipate that the software will not only be a significant time saver for our customers in a broad range of industrial process

manufacturing industries, but will also improve the accuracy and performance of the heat trace systems they design.“

|

Email Us

Email Us